Auto Brick making machine/ Concrete Block Making Machine

We supply complete auto bricks making machines and plants with installation and after sale services.

We also supply concrete block making machine in Bangladesh and India. Please click here if you want concrete block making machine instead of clay brick making machine.

Bricks are the only man-made building materials that testify to their use since the early human civilization. With their attractive appearances and superior properties such as high compressible strength and durability, excellent fire and weather resistance, good thermal and sound insulation, bricks are widely used for building, civil engineering work, and landscape design.

|

| Automatic unfired brick stacking machine |

|

| Auto Bricks Sample |

Bricks may also be classified as solid (less than 25% perforations by volume, although the brick may be “frogged,” having indentations on one of the longer faces), perforated (containing a pattern of small holes through the brick removing no more than 25% of the volume), cellular (containing a pattern of holes removing more than 20% of the volume, but closed on one face), or hollow (containing a pattern of large holes removing more than 25% of the brick’s volume). Blocks may be solid, cellular or hollow.

- A kiln, for firing, or ‘burning’ the bricks.

- Drying yard or shed, for drying bricks before firing.

- A building or buildings for manufacturing the bricks.

- A quarry for clay.

- A pugmill or clay preparation plant

Are you looking for cement or concrete block making machine? Please click here.

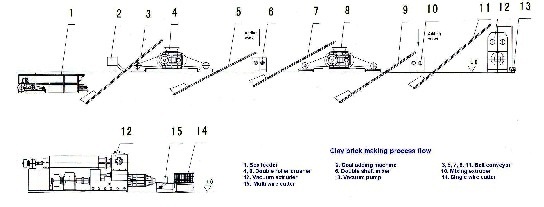

In a typical modern brickworks, clay is taken from the quarry, and then carried by conveyor belt or truck/lorry to the main factory, although it may be stockpiled outside before entering the machinery. When the clay enters the preparation plant (Clay Prep) it is crushed, and mixed with water and other additives which may include breeze, a very fine anthracite that aids firing. This process, which is also known as pugmilling, improves the consistency, firing qualities, texture, and color of the brick. From here, the processed clay can be extruded into a continuous strip and cut with wires, or put into moulds or presses (also referred to as forming) to form the clay into its final shape. After the forming or cutting, the bricks must be dried, either in the open air, in drying sheds, or in special drying kilns. When the bricks have been dried, they must then be fired or ‘burnt’ in a kiln, to give them their final hardness and appearance.

|

| Brick making process, with shale as raw material |

|

Model

|

Capacity (m3/h)

|

Conveyor belt

|

Conveyor width (mm)

|

Conveyor speed (m/s)

|

Power (kw)

|

|

GD650

|

9-35

|

Rubber

|

650

|

6

|

5.5

|

|

GD800

|

15-40

|

Rubber

|

880

|

5.3

|

5.5

|

|

GD1000

|

25-90

|

Rubber

|

1000

|

6

|

7.5

|

|

Model

|

Capacity (m3/h)

|

Conveyor belt

|

Conveyor width (mm)

|

Conveyor speed (m/s)

|

Power (kw)

|

|

GL800

|

20-35

|

Chain board

|

680

|

7

|

7.5

|

|

GL1000

|

25-40

|

Chain board

|

880

|

7

|

7.5

|

|

GL1200

|

30-50

|

Chain board

|

1080

|

7

|

7.5

|

|

Rubber belt conveyor width (mm)

|

Conveyor length(meter)/Powder (kw)

|

Conveying speed (meter/second)

|

Capacity (MT/hour)

|

||

|

500

|

≤12/3

|

12-20/4-5.5

|

20-30/5.5-7.5

|

1.3-1.6

|

78-191

|

|

650

|

≤12/4

|

12-20/5.5

|

20-30/7.5-11

|

1.3-1.6

|

131-323

|

|

800

|

≤6/4

|

6-15/5.5

|

15-30/7.5-15

|

1.3-1.6

|

278-546

|

|

1000

|

≤10/5.5

|

10-20/7.5-11

|

20-40/11-22

|

1.3-2.0

|

435-853

|

|

1200

|

≤10/7.5

|

10-20/11

|

20-40/15-30

|

1.3-2.0

|

655-1284

|

|

Item

|

SGP500

|

SGP600

|

SGP800

|

|

Manufacturing capacity, m3/h

|

13-18

|

17-23

|

23-26

|

|

Roller specifications, mm

|

500×500

|

600×500

|

800×500

|

|

Rollers interval, mm

|

3-5

|

3-5

|

3-5

|

|

Power, KW

|

7.5/10

|

10/13

|

18.5/22

|

|

Item

|

SJ2m

|

SJ2.5m

|

SJ3m

|

|

Mixing length, mm

|

2000

|

2500

|

3000

|

|

Power, KW

|

22

|

22-30

|

30-37

|

|

Model

|

Capacity, pcs/hour

|

Moisture content

|

Vacuum degree (Mpa)

|

Extrusion pressure (Mpa)

|

Power (KW)

|

|

JZK90Y-4.0

|

20000-25000

|

11-14%

|

≦-0.092

|

4.0

|

132+315

|

|

JZK75Y-4.0

|

15000-20000

|

11-14%

|

≦-0.092

|

4.0

|

110+250

|

|

JZK60Y-4.0

|

11000-13000

|

11-14%

|

≦-0.092

|

4.0

|

90+160

|

|

Model

|

Capacity, pcs/hour

|

Moisture content

|

Vacuum degree (Mpa)

|

Extrusion pressure (Mpa)

|

Power (KW)

|

|

JKY60/60-4.0

|

16000-22000

|

15%-18%

|

≦-0.092

|

4.0

|

200+90+22

|

|

JKY55/55-4.0

|

14000-19000

|

15%-18%

|

≦-0.092

|

4.0

|

200+75+22

|

|

JKY50/50-4.0

|

12000-16000

|

15%-18%

|

≦-0.092

|

4.0

|

160+75+22

|

|

JKB55/55-3.0

|

12000-16000

|

17%-19%

|

≦-0.092

|

3.0

|

160+55

|

|

JKB50/50-3.0

|

10000-15000

|

17%-19%

|

≦-0.092

|

3.0

|

132+55

|

|

JKB45/45-3.0

|

8000-12000

|

17%-19%

|

≦-0.092

|

3.0

|

110+45

|

|

Model

|

Capacity, pcs/hour

|

Moisture content

|

Vacuum degree (Mpa)

|

Extrusion pressure (Mpa)

|

Power (KW)

|

|

JZKE50-3.0

|

12000-16000

|

17%-19%

|

≦-0.092

|

3.0

|

160+7.5

|

|

JZKE45-3.0

|

10000-15000

|

17%-19%

|

≦-0.092

|

3.0

|

132+5.5

|

|

JZKE40-3.0

|

8000-12000

|

17%-19%

|

≦-0.092

|

3.0

|

110+5.5

|

|

JK35-2.0

|

6000-8000

|

18%-22%

|

≦-0.092

|

2.0

|

75

|

|

JK30-2.0

|

5000-7000

|

18%-22%

|

≦-0.092

|

2.0

|

45

|

|

Type

|

Production Capacity (Pieces/Hour)

|

Weight (Kg)

|

Dimension (mm)

|

|

ZMP460×2

|

4600

|

13500

|

8000×5980×7570

|

|

ZMP690×3

|

7400

|

14000

|

11500×6010×6610

|

|

ZMP460×2×2

|

8615

|

16500

|

12440×6010×6610

|

|

ZMP923×4

|

8615

|

16500

|

12440×6010×6610

|

|

ZMP731×3×2

|

11270

|

9000

|

11850×3782×5000

|

|

ZMP3×2A

|

12960

|

16264

|

17390×6680×6453

|

- Wet adobe car

- Dry adobe car

- Automatic lifting and transporting vehicle

|

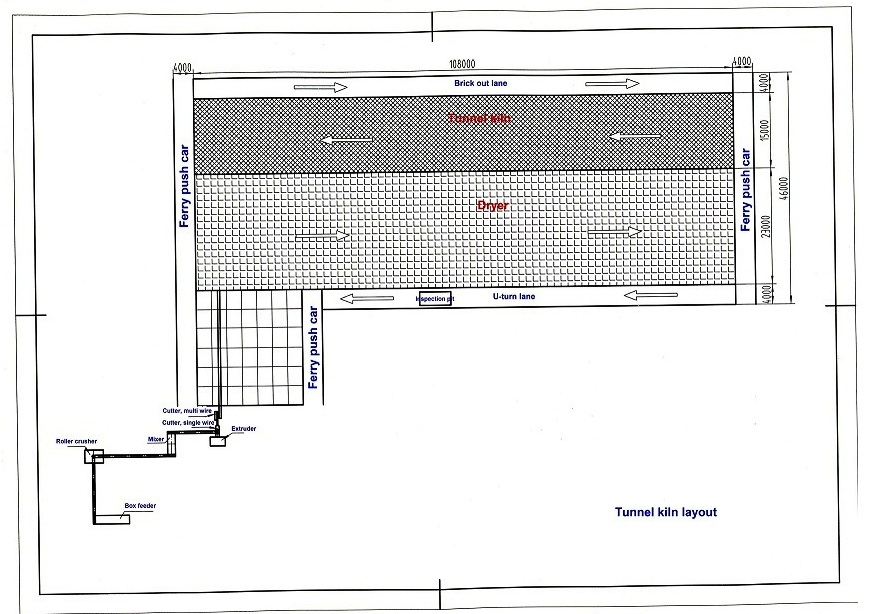

| Hoffman Kiln & Dryer Layout |

We supply all kinds of auto brick making machines, complete auto brick production line, turn key solution. Please contact us for detail information and quotations.